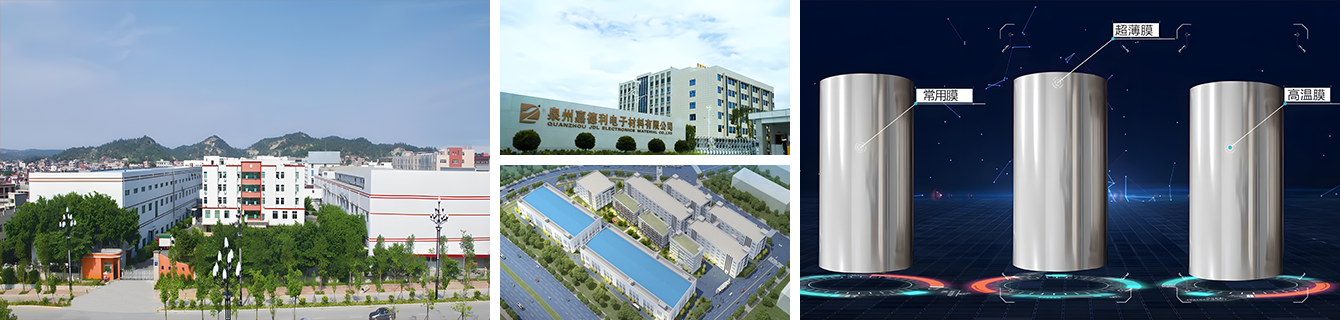

Quanzhou Jiadeli Electronic Materials Co., Ltd. was established in 2002. It is a high-tech enterprise that integrates scientific research, development, and production, specializing in the production of high-quality polypropylene films for capacitors. The capacitor film product series is the most complete in the same industry, with a leading position in technology and product quality. It is mainly used in traditional fields such as household appliances, electronics, and power, as well as emerging fields such as high-speed rail and new energy vehicle capacitors. It is one of the largest professional manufacturers of capacitor films in China and a leading supplier of high-end capacitor films in China. It has been awarded honors such as "National Specialized, Refined, New and New Little Giant", "High tech Enterprise", "Famous Brand Product of Fujian Province", and "Single Champion of Fujian Province's Manufacturing Industry".

The company invested 35 million euros to introduce a full set of polypropylene film production line for Brukner capacitors and a complete set of laboratory testing equipment, and is equipped with Atlas high-speed cutting equipment and CommScope cutting machine. At present, Jiadeli has a total of 6 production lines, including the Bruckner Lisim with bidirectional synchronous stretching. Based on these, our current annual production has reached 10000 tons.

Our capacitance film is divided into three series, among which ultra-thin film and high-temperature film have significant competitive advantages, and the product thickness covers the range of 1.9 microns to 14.8 microns. As an enterprise certified by ISO9001:2008 and TS16949:2008 quality management systems, with the continuous efforts of an experienced engineer and QC team, we have established a good corporate image in the industry with superior quality.

Diligence leads to diligence, but idleness leads to leisure. The footsteps of success are bound to be full of challenges. Standing at the threshold of the 21st century, looking ahead to the world, technology is advancing rapidly. The development of technology stems from striving for progress and accumulating experience. Looking back at the footprints of global economic development, we deeply understand that winning customers and markets requires relying on high paying technology and modern concepts, leveraging the professional knowledge and experience of outstanding talents, and comprehensively improving the product level and competitiveness of enterprises. We believe that Jiadeli's high-quality products and "more satisfying service than customer satisfaction" will win your visit.

Corporate spirit: "Putting people first, striving for progress, and promoting development through technology".

Corporate aspiration:To pursue a win-win goal with customers, employees, and relevant interest groups.

Corporate mission: To create value for customers, and in the process of meeting customer and market needs, the company and employees achieve survival and development.

Core values:Integrity is the foundation of human behavior, and integrity is the long-term strategy for the continuous development of enterprises.

Core competitiveness: Increase investment in scientific research and equipment, enhance the technological content of products, and provide customers with high-quality products and comprehensive services.

The fifth production line will be put into operation in October 2023, and the installation work for the sixth production line will be carried out in the same year.

The fourth Brookner BOPP production line was put into operation in April 2019, with a full width of 6.2 meters equipped with a CommScope slitter.

The third Bruckner synchronous stretching production line has started operation, with a full width of 5.8 meters, and is the first to achieve bidirectional synchronous stretching technology.

The second Brookner BOPP production line has been put into operation, with a full width of 5.8 meters equipped with a CommScope slitting machine.

Founded in May 2002, the first Brookner BOPP full-automatic production line was introduced and put into production the next year, with a full width of 4.6 meters and Atlas slitter.